Case Study: Upgrading CRAC Systems from R22 to CO2

About this Project

Tier 5 Systems navigated the challenge of maintaining server room temperatures while replacing outdated R22 CRAC units and Upgrading CRAC Systems with advanced Carnot CO2 CRAC equipment, amidst unexpected equipment failures. By implementing temporary cooling solutions and employing precision techniques such as orbital welding for stainless steel piping, the team not only overcame manufacturing errors but also ensured the project's success, maintaining their commitment to delivering high-quality mechanical solutions.

Case Study

The Challenge

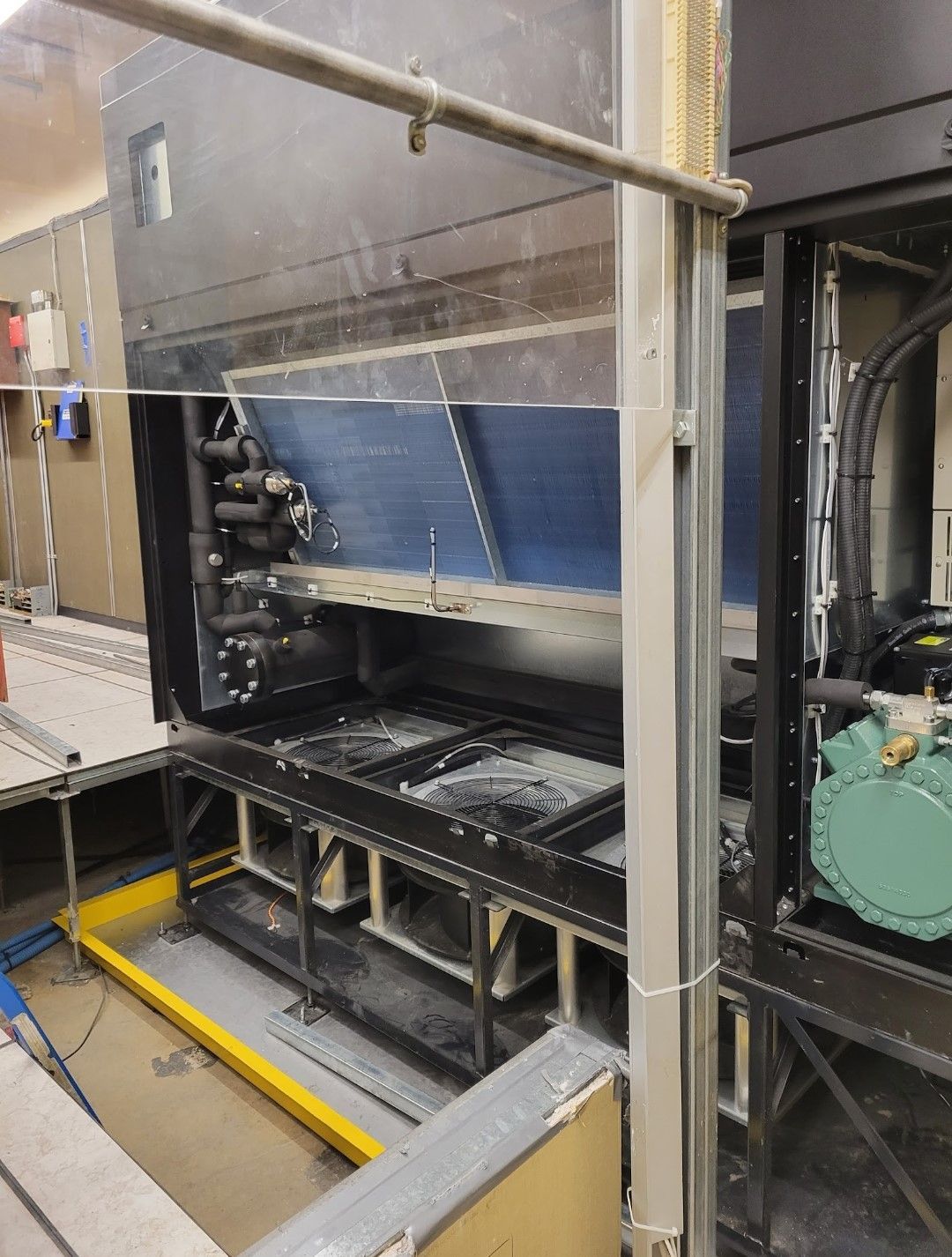

Maintain server room temperatures while replacing cooling equipment became a larger task when the 2nd CRAC unit failed during construction. Plans needed to be adjusted as it was opportune to remove the un-planned CRAC unit now while initially planned unit was being removed. Extra temporary cooling was installed. Method of Procedure was approved which included hoarding to protect electrical gear while old equipment was being removed.

What We Did

Two obsolete R22 air cooled CRAC units to be completely removed from building. New equipment is Carnot CO2 CRAC equipment. CO2 refrigerant needs to be installed in stainless steel piping with all changes in direction being bent (no fittings). We use an orbital welding rig to weld the stainless steel piping and then pressure test to 2,100 PSIG.

What We Achieved

The equipment arrived with certain electrical system flaws, but our proficient team of technicians successfully pinpointed and rectified each issue. Our team oversaw all mechanical aspects of the project, ensuring the high standards our customers anticipate were met and the upgrading CRAC Systems was fully implemented.